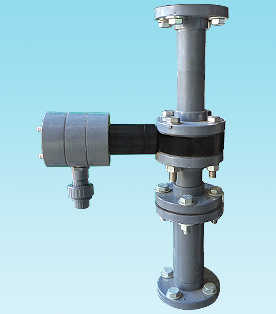

The ejector creates a vacuum in the system by virtue of water under pressure passing through its venture and opening the check valve. This spring opposed the check valve prevent water entering the vacuum gas pipe work on shut down of the system. The gas entering the ejector under vacuum via the check valve is vigorously mixed with the incoming water flow prior to injection in to the water to be treated.

The ejector creates a vacuum in the system by virtue of water under pressure passing through its venture and opening the check valve. This spring opposed the check valve prevent water entering the vacuum gas pipe work on shut down of the system. The gas entering the ejector under vacuum via the check valve is vigorously mixed with the incoming water flow prior to injection in to the water to be treated.

Capacity : 10 Kg/Hr to 200 Kg/Hr

Maximum back pressure : 10 LBS

Water inlet connection : 2” to 4” PVC Flange As per ANSI Standard

Solution out let connection : 2” to 4” PVC Flange As per ANSI Standard

Vacuum gas connection : 25mm to 40 mm PVC union

Technical Data

Material of Construction : CHLOROTECH Chlorinator is non-corrosive to dry and moist Chlorine gas and Chlorine solution where necessary.

Regulator Body : Ebonite , P.V.C. or A.B.S.

Regulator Diaphragm: P.T.F.E. or C.T.F.E

Regulator Valve : Silver.

Ejector Block : Ebonite, P.V.C or A.B.S.

Springs : Silver plated silver alloy.

Overflow and Check Valve : Precision balls and seat P.T.F.E. or P.V.C.

Chlorine Gas Vacuum Piping : P.V.C.

Flow Meter Tube : Heavy wait., precision Bore Glass Borosilicate.

Metering Floats : (Low flow rates) P.V.C. or P.T.F.E.

Metering Floats :(High flow rates) Silver or P.V.C.

Type Operation : Vacuum

Control : Manual of Semiautomatic

Range of Operation : 20 : 1 set by hand.

Accuracy : +/- 4%.

Cabinet : Special steel ,polyester-gray colour.